Farms and Food & Beverage Industries are under strict regulations for waste management - still, unmanageable algae blooms from excessive waste nutrients are causing human and environmental health issues as well as losses in water-related industries and related real estate businesses. THEY ARE ALL SEEKING A BETTER SOLUTION!

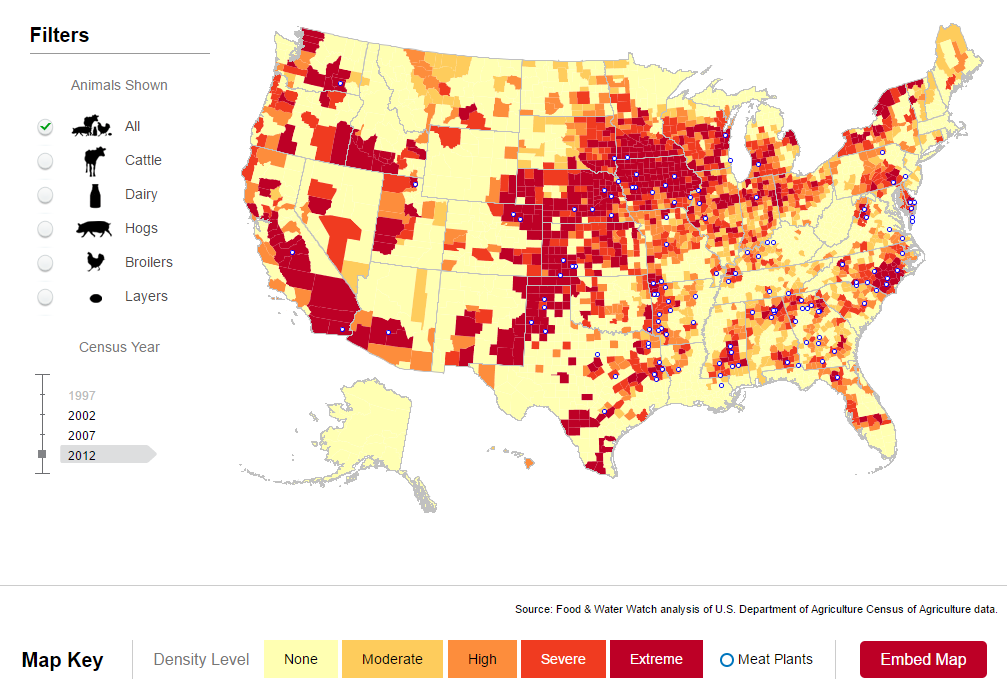

Livestock and poultry on the largest factory farms produced 369 million tons of manure in 2012 — almost 13 times more than the 312 million people in the United States.[1] This 13.8 billion cubic feet of manure is enough to fill the Dallas Cowboys stadium 133 times.[2] Household waste produced in most U.S. communities is treated through municipal sewer systems, but factory farm manure is stored in lagoons and ultimately applied, untreated, to farm fields as fertilizer (Food & Water Watch). Globally, about one-third of food is wasted: 1.6bn tonnes of produce per year, with a value of about $1 trillion. If this wasted food were stacked in 20-cubic-meter skips, it would fill 80 million of them, enough to reach all the way to the moon and encircle it once over[3].

[1] USDA National Agricultural Statistics Service. 2012 Census of Agriculture. United States Summary and State Data at Tables 11, 12 and 20; Food & Water Watch calculation comparing human and livestock waste production based on EPA (2004) at 9. [2] USDA Natural Resources Conservation Service. “Agricultural Waste Management Field Handbook.” Chapter 4, Agricultural Waste Characteristics. March 2008 at 4-12 to 4-20; Dallas Cowboys. [Press release]. “Dallas Cowboys Stadium Design Statement.” December 12, 2006. [3] Half of all US food produce is thrown away.The Guardian. Jul 2016 Photo source: Food &

Water

Watch

Photo source: Food &

Water

Watch

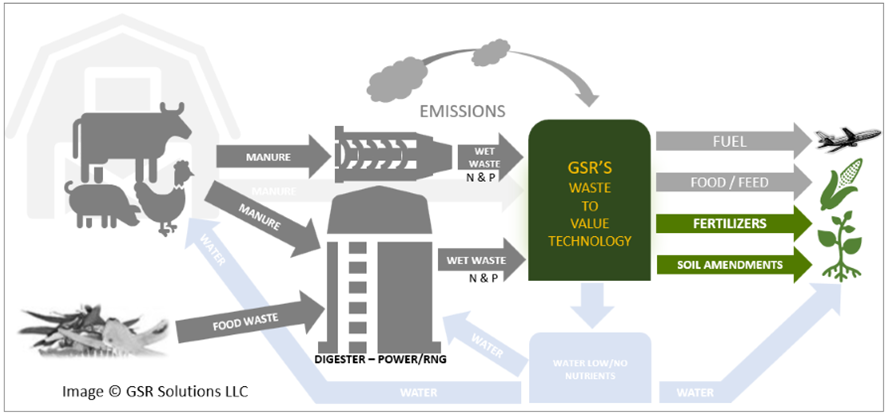

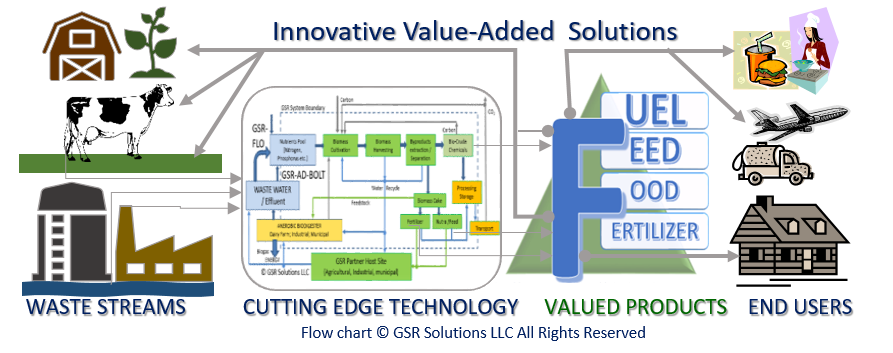

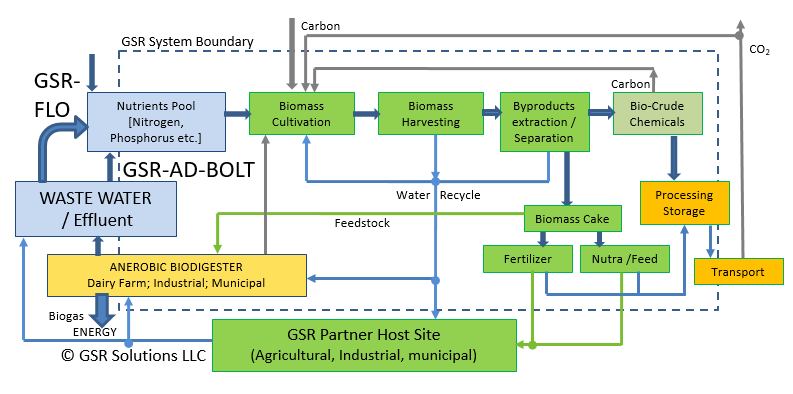

GSR's patented, scalable, bolt-on platform changes the waste nutrient management game - it converts the rapidly growing problem of excessive nutrients into an enormous opportunity by generating new revenue sources from recovered nutrients and saving on treatment costs both nationwide and worldwide. GSR's process combines cutting edge technological advances with mass production of the fastest growing biomass feeding on excess nutrients to convert waste into valued products for the fastest growing food, water, and energy markets.

Food & beverage Industries and Livestock farms generating wastes and effluents containing excessive nutrients are our potential partners. They are required to meet standards for the handling and recycling of wastewater nutrients per guidelines from state and federal regulatory agencies.

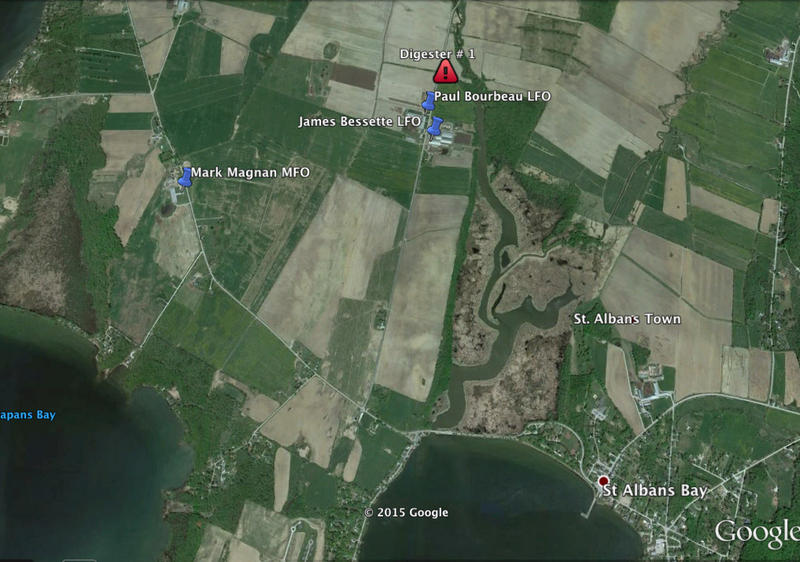

Photo source: Google Maps

Photo source: Google Maps

Photo

source: Green

Mountain Power Google Map in VPR News

Photo

source: Green

Mountain Power Google Map in VPR News

Commonly used anaerobic biodigester systems for the treatment of waste are effective mostly in treating the biochemical oxygen demand (BOD), but not nutrient (nitrogen and phosphorus) removal. This effluent coming out of biodigesters needs to be further treated before it can be recycled at a farm or discharged into water streams as per water quality regulations, and several host sites cannot manage such a system.

GSR's bio-based technology serves sites both with or without a digester. After the pre-treatment process, GSR utilizes advanced microbial-based biomass, which is relatively quick to grow, as its microalgal component captures nutrients and carbon dioxide, utilizing the symbiotic potential between microbial communities.

This bio-based process is responsible for the removal of effluent components from wastewater. The mature biomass material is separated and processed into target molecules and products, and the clean water is recycled. Some of our proprietary processes also utilize other bio-based materials such as biochar.

GSR's patented, scalable, bolt-on platform changes the bioenergy production game - it converts the rapidly growing problem of excessive nutrients into an enormous opportunity by generating new revenue sources from recovered nutrients and saving on treatment costs both nationwide and worldwide. GSR's process combines cutting edge technological advances with mass production of the fastest growing biomass feeding on excess nutrients to convert waste into valued products for the fastest bioenergy markets.

Food & beverage Industries and Livestock farms generating wastes and effluents containing excessive nutrients are our potential partners. They are required to meet standards for the handling and recycling of wastewater nutrients per guidelines from state and federal regulatory agencies.

GSR offers unique solutions to rethink how digesters are designed and operated, to maximize the economic and environmental performance of digesters, and to convert unmanageable waste nutrient effluents from digesters into many high-value marketable products.